Meet Loveland’s aerospace industry pioneers: CisLunar Industries

Metal recyclers and power providers in outer space

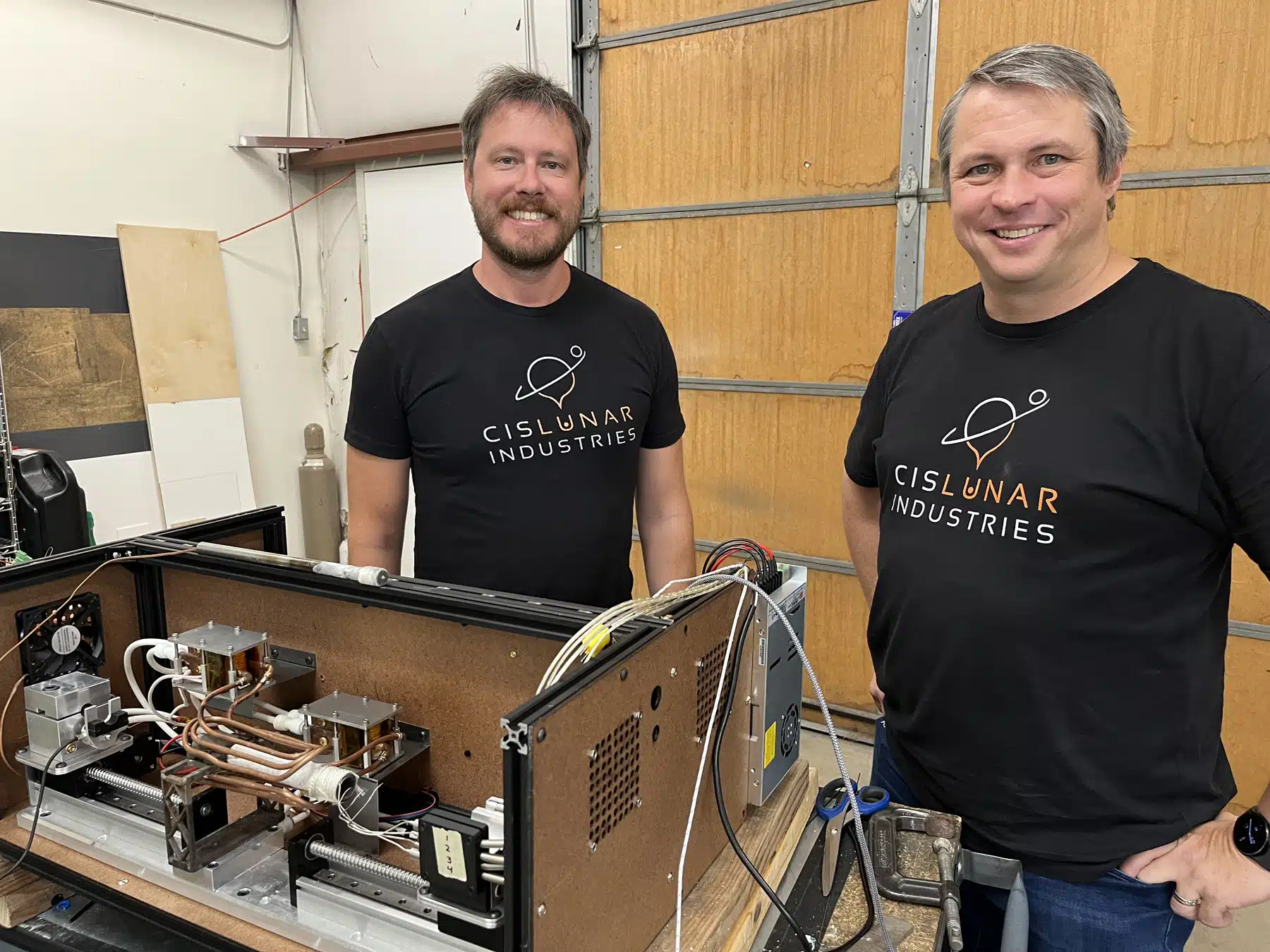

LOVELAND — It’s not hard to feel a little lost in space when listening to Gary Calnan and Joe Pawelski talk shop as aerospace industry pioneers. The principals in one of Loveland’s handful of aerospace companies sound as if they’re coming right out of a science-fiction novel.

Seamlessly, words such as “electric propulsion systems” and “power processing units” and “space foundries” and “radio frequency technologies” weave into their everyday conversations, so bone up on your space lingo.

For those on the ground, officials in NASA, professors, even many aerospace companies they work with, their 5-year-old space startup — CisLunar Industries USA, Inc. — is literally on the cutting edge of space from a small shop with a garage door.

SPONSORED CONTENT

Space cowboys

In their short time, CisLunar Industries won three awards worth almost $2 million from NASA to bring their ideas to reality. Their big-picture theme is to become the first steel mill in space, through which they hope to recycle space debris and repurpose it into rods, plates, wires, even fuel for manufacturing in space.

From its lab in an older part of Loveland, the CisLunar team has been riding high on its patience and patents with the goal of becoming a major power and metal provider in space before the decade is out. The pair, along with their small troupe of electrical and mechanical engineers, took an unstudied idea of metal recycling in space and turned it into a game changer for space companies all over the world — in more ways than one.

In researching and working toward this end, they have discovered an electronic solution for space-power conversion that has become self-sustaining and fuels their coffers to find the next great space technology.

“We really are very cognizant of continuous improvement and think of ourselves that way above all else,” said CisLunar co-founder Joe Pawelski. “We know what’s needed (for the space industry) because we are building that economy.”

The grand vision

Calnan is a former finance director in Centennial, while Paweslki is a former Loveland manufacturing engineer who invented new manufacturing methods for aluminum cans.

Their unlikely trajectories toward an aerospace business began at the International Space University in Ireland in 2017. There, Calnan met other company co-founders. Just before the pandemic, he met Pawelski from connections with the Colorado School of Mines. He helped write CisLunar’s first proposal to NASA.

“We won it, and we were off to the races,” Calnan said.

“People have often envisioned a future in which we are building large structures in space,” Calnan said, “but except for building the international space station, where we brought it up in sections and assembled it, we haven’t assembled large objects in space.”

That’s chiefly because the technology to provide the power to build and construct in space hasn’t been available. That is, to manufacture in space — especially melting metal — without the aid of gravity has been a tricky mistress. But they’re battling.

If they’ve lost you thus far, just think of it this way: “When we were going to the moon the first time, that was like Lewis and Clark,” Pawelski said. “There was some really good science, and now we need to start building a railroad because there’s people coming out in covered wagons.”

The problem in space

There’s a scene in the movie “Gravity” in which astronauts are working on their space shuttle in orbit, and space debris crashes into and destroys it.

It has been estimated that more than 23,000 pieces of derelict space debris have been traveling around the earth. There is a very real concern of the damage the debris field can cause as it grows larger, as humans put more satellites in orbit. At present, according to a PBS report, there are more than 7,700 satellites in space. But that number is growing all the time, and space debris travels at more than 15,000 miles per hour.

“‘Gravity’ is a good illustration to show the potential dangers of space debris,” Calnan said. “It’s getting worse, and we’re trying to create a way to make all the material more valuable. Let’s use it where it is, and let’s not dump stuff in the atmosphere as we start to do more of this activity.”

“If you could remove (the debris) that are the most derelict, the chances of the debris field causing problems launching” would be lessened. “It could be huge,” Pawelski added. “The best thing to do is to remove it before it becomes a part of the debris field, and if your satellite is coming to the end of its life, bring it on over to us. Maybe we’ll re-use it, salvage it, put a new motor in it or melt it down,” Pawelski said.

While they have come up with the foundry to melt metal to recast it into the building blocks for space manufacturing, it’s not yet to scale, and other players in the market aren’t quite there.

Enabling the space economy

Calnan and Pawelski call themselves the “enablers,” of the power to manufacture in space. Still, the space trucks, robotics and equipment have not yet been established or found a home in space. That is all coming.

The commercial space marketing industry took off in the last few years — in Colorado alone, there are about 400 companies “who are leading and supporting groundbreaking missions related to space and planetary science,” according to the Colorado Office of Economic Development and International Trade.

Solving the problem of recycling in space was a part of the grand scheme eventually. That was the original theme in the first of their three NASA awards.

In their research and buildup toward their eventual recycling model, Cislunar principals are finding the gaps in technology, through which they can provide solutions to other problems of functioning in space long-term. The solutions they develop help keep their business model running so they can spend time on R&D for the recycling piece.

“We looked at the value chain and figured out where someone needed to make progress,” Calnan said. “We’ve mapped out all the gaps in technical development. We just try to find opportunities to go after them. We figure out what people need and step by step we add opportunities, and as we succeed, people give us more.”

So far, CisLunar Industries has come up with a popular electronics solution, which is generating revenue for the company to pursue its continued work on the space-recycling process.

“If we have the power electronics business generating, we can keep developing technology for metal processing, and when that market comes, we’ll be ready,” Calnan said.

Inching closer

In November 2022, the company tested their space foundry — a system by which they melt metal and cast it into shapes to cool — in a 22-second parabolic flight. This May, high voltage power electronics hardware spun off from this technology flew to space. In that flight, Boulder-based ThinkOrbital Inc., another company focused on space manufacturing, successfully powered an autonomous welder with CisLunar’s technology. In that short burst into the atmosphere, they were able to melt metal in microgravity, showing it could be done.

“Our first ever in-space autonomous welder would not be possible without their incredible and now space-proven high voltage power supply,” ThinkOrbital CEO Lee Rosen said in a news release.

“Creating this welding technology is a paradigm shift for what’s possible,” Calnan said.

The problems to solve now are controlling the temperature and speed of their system in microgravity, so they can actually cast melted metal into other objects. As an example, aluminum starts to melt at 600 degrees Celsius, but it boils at around 2,000 degrees Celsius, Pawelski said. There’s a lot of room for error in between. Once they figure out many aspects of this melting and cooling process sans gravity, they can put the data into their computers to make a 3D model and scale it.

“We need to prove we can do it in a sustained operation,” Pawelski added.

“What’s different about space is there’s no gravity, so the metal wants to flow, and the heat doesn’t move the way it usually does,” he said. “Without gravity, it totally changes how all of this interacts.”

What’s next?

CisLunar’s team keeps researching and working toward the recycling piece, and on the way, they are working on solutions from an unassuming lab in a cluster of other small businesses.

They say there is a lot to being in the right space at the right time, but dogged determination also must be present. While working on their space foundry system and recycling ideas, they discovered they could fulfill an electronics need in the industry.

“We have this commercial business of power, and there is pent-up demand for what we’re making. That’s the today business,” Calnan said. “The big business is really to be the steel mills of space. We think there is a place for that in the next industrial economy. We just don’t know when that will happen. But on the current trajectory, that kind of industrial activity could start to become real by the end of this decade.”

In fact, the company, because of one of their NASA awards, is scheduled to bring their research back into space at the end of 2025. “We are slated to begin station operations in 2026. We will get to fly our Space Foundry Payload to space and get so many hours of an astronaut’s time,” Pawelski said to set it up and operate it. That flight and time, alone, is worth millions, he said. That 22-second flight in November and suborbital flight this spring was the springboard for their system for the time it’s in the hands of an astronaut.

To make it all happen — recycling space debris, melting metal and reusing that material into usable building blocks in space — is going to rely on other companies working to put the industrial pieces in space in the first place.

“If you believe in the industrial economy of space, there’s going to be a need for the person who takes it from one form to another,” Calnan said. They are determined to be in the right place at the right time — if anything to fulfill some youthful dreams in the stars.

Loveland's CisLunar Industries principals solve problems for companies while pursuing space debris recycling business.

THIS ARTICLE IS FOR SUBSCRIBERS ONLY

Continue reading for less than $3 per week!

Get a month of award-winning local business news, trends and insights

Access award-winning content today!