Aerospace company produces compact, feather-light gear for space

LOVELAND — It’s a bit obscure, and has almost nothing to do with the Loveland company Opterus Research and Development Inc., but at one time the founder of the aerospace company leasing space at the Forge thought he would use his invention to build even better fishing rods for bass fishing.

The black bass is known in scientific circles as micropterus salmoides. Thomas Murphey, the founder of Opterus, hoped to develop highly engineered composite fishing rods — you know, the kind that seem to bend almost in half without breaking as an angler tries to land that trophy fish.

Instead, outer space called, and Murphey turned his invention into a raw material for products that could support aerospace and enable large structures to be transported into space in tiny boxes.

SPONSORED CONTENT

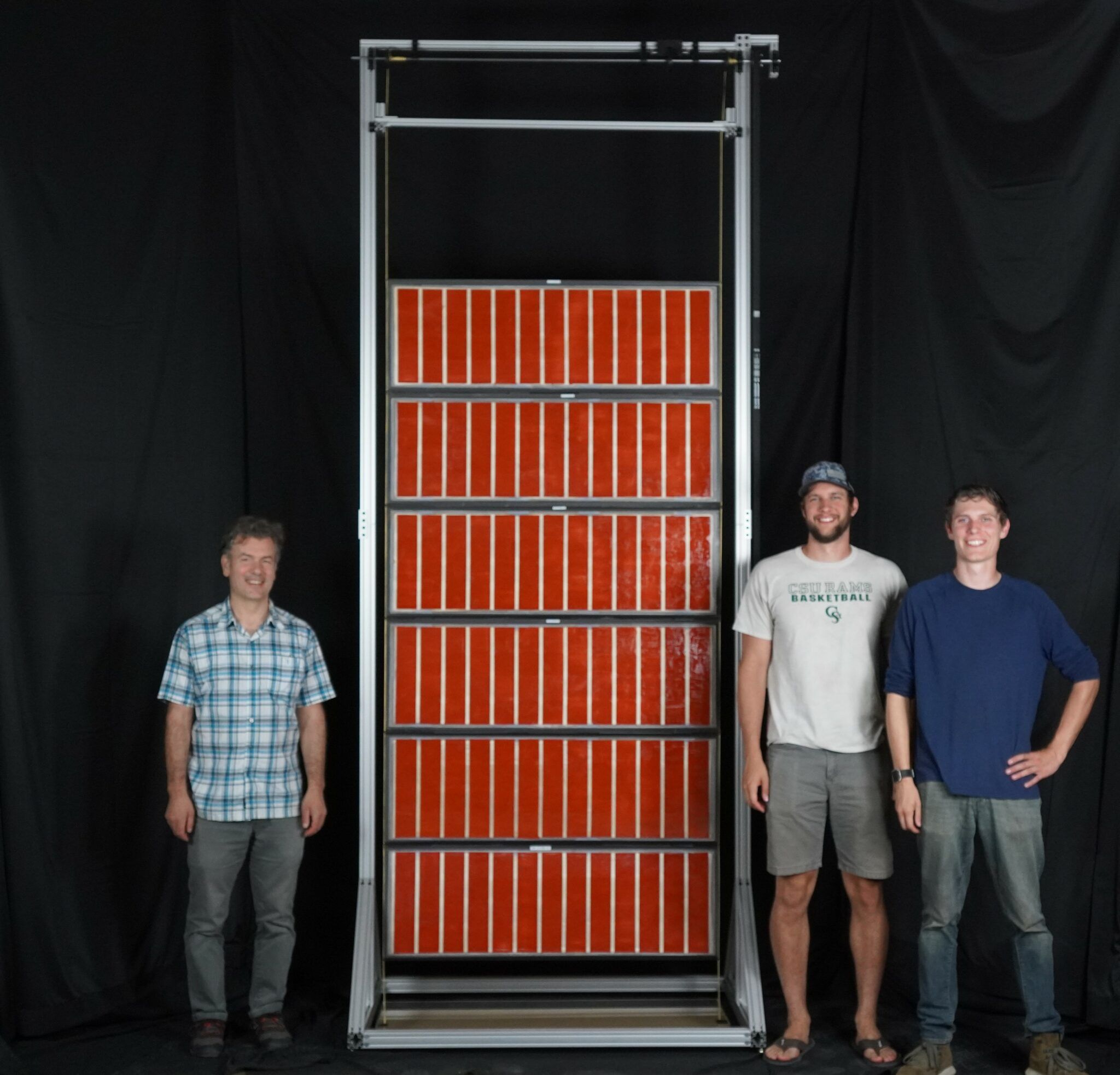

Opterus Research and Development Inc. has developed a material called High Strain Composites that is as light as a feather and strong enough to bear the weight of a 200-pound solar array on the moon, or heavier if needed. And it comes packed in small containers suitable for launch into space without taking up too much valuable cargo space.

Opterus, like a rocket on a launch pad, is set to blast off thanks in part to a grant from the city of Loveland that permits the company to expand.

Opterus signed an agreement with the city this summer to receive a $30,000 grant and in exchange to add 33 technology jobs to the operation over the next five years. It’s actively hiring engineers, when it can find them, and average pay for Opterus staff members is $100,000 a year.

While the company is confident of adding that number of jobs, four developing product lines running in parallel could produce even faster growth.

Opterus is an aerospace company that began in 2015. It is located at The Forge Campus — the former Hewlett-Packard Co. (NYSE: HPQ) facility — in south Loveland.

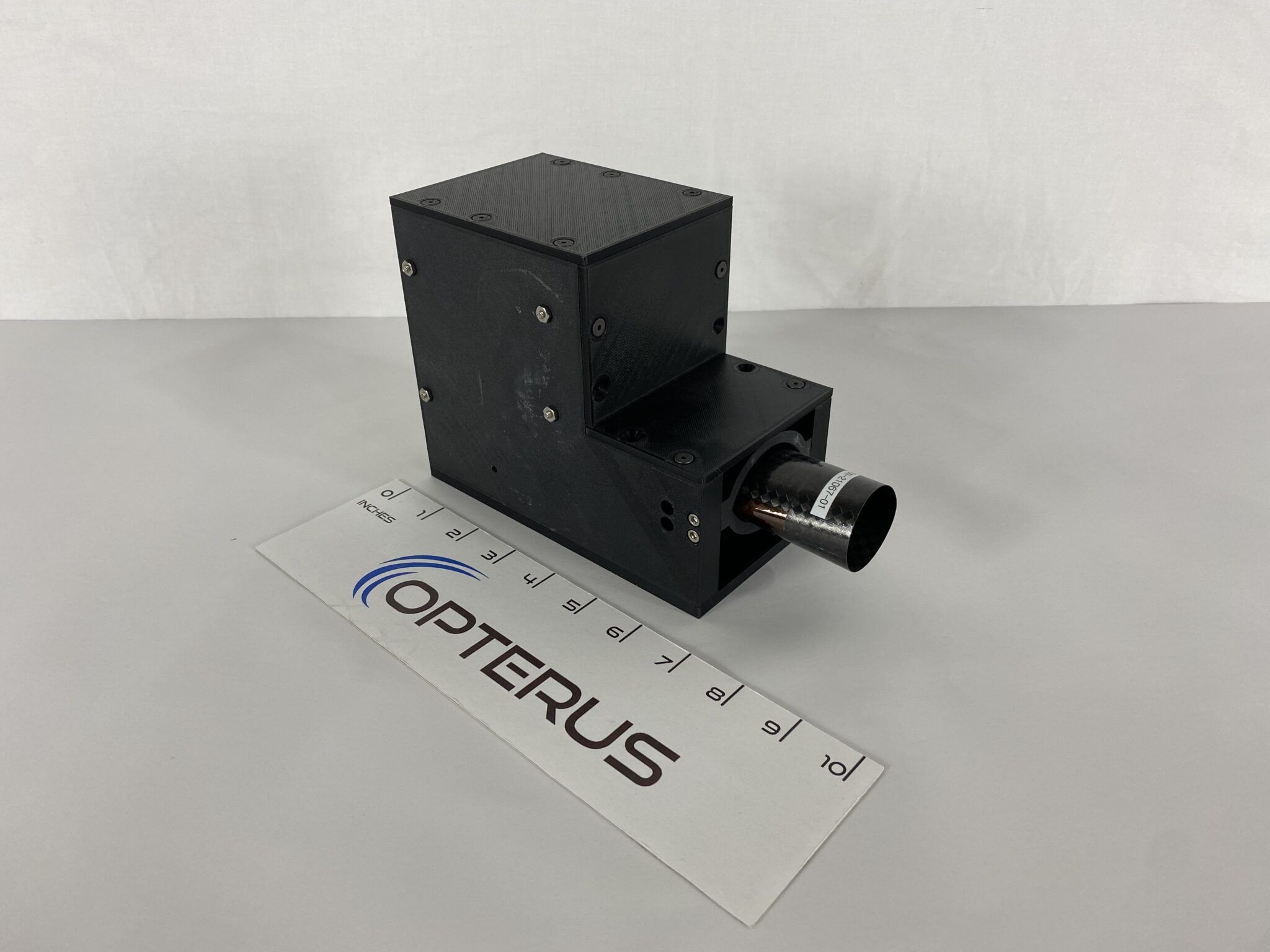

The grant enabled Opterus to move from a 4,000-square-foot facility to more than 9,000 square feet in what was HP’s Building C. In that space, 17 engineers and technicians work to produce a light, high-strength composite material made from flexible carbon fiber. The material is pulled from freezers, shaped into booms and antennas, baked in ovens, rolled into tiny packages and made ready to blast into space where it will be deployed on spacecraft or space stations when unrolled and positioned.

Clients such as the U.S. Department of Defense, NASA and private aerospace companies look to Opterus to produce rigid structural supports, for example, that can be stowed in a shoebox-size package and deployed out five to 30 meters in space.

To the untrained eye, an Opterus boom in its compressed state might resemble a metal tape measure that can be pulled out of a compact package to measure something along its extension. But it’s lighter than metal and far, far more stable than the flopsy tape measure. The deployed material might be in the shape of a round tube or a hollow diamond-shaped tube.

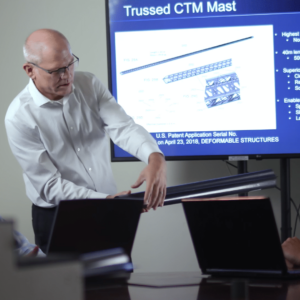

Developed by company founder Murphey, the material came out of his work with the U.S. Air Force Research Lab where he started and led the space development group.

“We’re putting that work into new technology,” he said. The company’s booms and other inventions have patents pending, he said. “We’re the only supplier of closed cross-section booms,” he said. “We’re discovering all the things we can do with it.”

Erik Pranckh, director of business development and engineering program manager for Opterus, and Murphey outlined four product lines that have potential for the company. If any one of them takes off, the targeted employee count easily occurs. More staffing would occur if multiple product lines take flight.

The four:

- The material can be fashioned into booms to support technologies that are used in space.

- It can be used to support solar arrays that can be stowed into small containers that are unfolded in space.

- It is used on parabolic reflectors — communication dishes, for example. Again, it would be folded or rolled, then deployed in space to its full size.

- And it has applications for in-space manufacturing.

“If any one goes big, we’re there,” Pranckh said.

The process used to make and fashion booms and other devices is well developed and fast. A high-performance communication dish, for example, can be made in a day with one technician where older technologies may have taken multiple technicians weeks to do the same thing.

While some of the company’s products are already deployed in space, some are still being tested. NASA will send samples of the product to the International Space Station to test its reflective reliability in space, for example.

Murphey said the material has applications throughout the aerospace industry, but small satellites especially benefit because it gives them greater capability. And a contract with a company planning a constellation of small satellites would be especially beneficial to Opterus, while also driving down the unit cost for the satellite company.

Within the Opterus facility, several freezers store the raw material before it is taken out and shaped into its end product. The material will harden and become difficult to shape if left at room temperature for long. Then, the shaped material is placed in an oven to cure. A wall of ovens lines one side of the facility, all built in house by technicians. Opterus is working toward building 30-foot booms, which require the oven configuration.

The company is confident that it has products useful for government or commercial space operations. It is still seeking financing for qualification testing. A solar array built in the lab in Loveland was just shipped to the NASA Glenn Research Center in Cleveland, where it will be on display to garner support for further development of high power, compact solar arrays for next-generation spacecraft architectures, Pranckh said.

A combination of private-industry funding coupled with a government match are likely the sources for the flight demonstrations that need to occur.

© 2021 BizWest Media LLC

LOVELAND — It’s a bit obscure, and has almost nothing to do with the Loveland company Opterus Research and Development Inc., but at one time the founder of the aerospace company leasing space at the Forge thought he would use his invention to build even better fishing rods for bass fishing.

The black bass is known in scientific circles as micropterus salmoides. Thomas Murphey, the founder of Opterus, hoped to develop highly engineered composite fishing rods — you know, the kind that seem to bend almost in half without breaking as an angler tries to land that trophy fish.

THIS ARTICLE IS FOR SUBSCRIBERS ONLY

Continue reading for less than $3 per week!

Get a month of award-winning local business news, trends and insights

Access award-winning content today!