AtmosZero seeks to transform industrial heating systems

FORT COLLINS — One can only wonder. When George Babcock and Stephen Wilcox invented the water-tube boiler in 1867 in order to quickly generate steam that would propel the industrial revolution, did they think that their invention would continue to be used 157 years later?

And that their boiler would, as the world became more concerned about environmental impacts of generating power, contribute a significant share of all industrial emissions?

Likely not.

SPONSORED CONTENT

A Fort Collins company soon to expand into 100,000 square feet of space at the Forge Campus in Loveland saw that the time had come to improve the efficiency and efficacy of the Babcock and Wilcox boiler. Its “boiler 2.0,” as the company founders call it, will use heat pump technology to replace traditionally powered boilers that generate steam for industries from breweries to building heating systems.

The company, AtmosZero Inc., is one of four winners of BizWest’s IQ (Innovation Quotient) Awards, which were unveiled in May. The company was founded by CEO Addison Stark chief operating officer Ashwin Salvi and Todd Bandhauer, a CSU professor of mechanical engineering. Stark also has a mechanical engineering degree.

Stark, who previously worked in Washington, D.C., government circles and knew Bandhauer in a different context, said he called Bandhauer to say he would quit his job if they could come up with a heat-pump powered steam boiler to help solve the environmental emissions problem caused by heating water for steam.

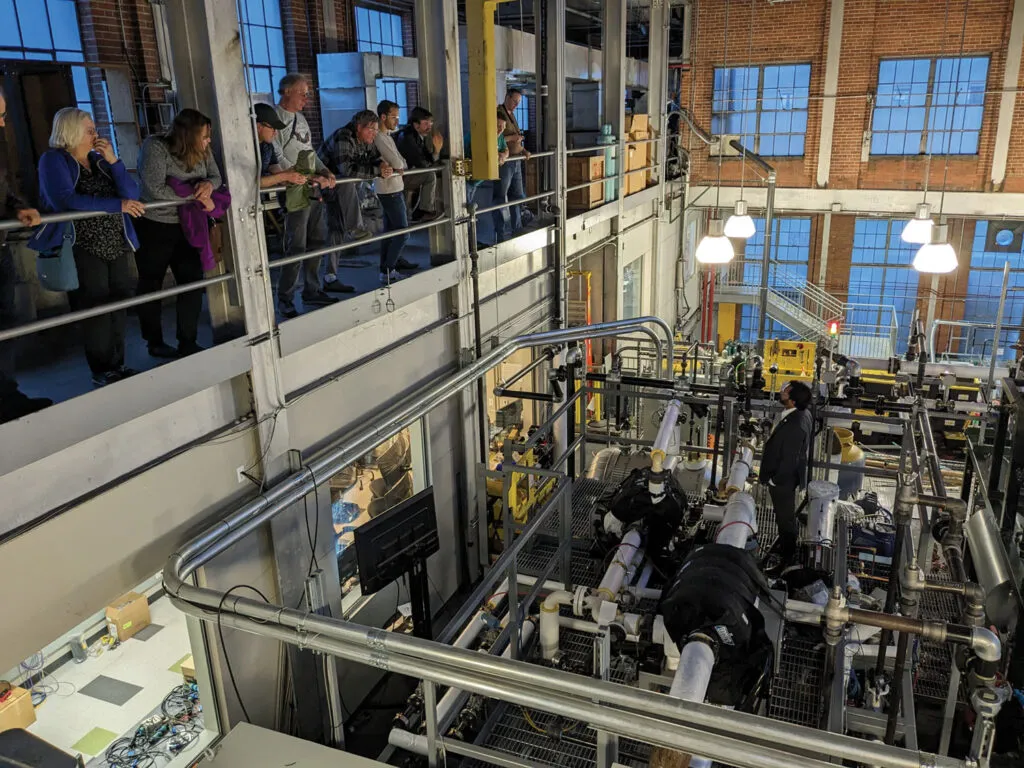

So they did, and he packed up his family and moved to Fort Collins. The company headquarters has been at Colorado State University’s Powerhouse campus and a presence will remain there even after production moves to Loveland. The company employs 23 people now and will grow to about 40 within 18 months, Stark said.

“The kernel for the company came in 2020 with ‘why is industry so hard to decarbonize,’” he said. Environmental experts were projecting it would be 2040 before progress could be made.

Stark said industrial steam seemed to be a good area to start looking at innovations because it offered “the best opportunity to discover a cost effective way to process heat.”

Three fourths of industrial emissions come from producing processed heat, and half of that is steam, he said. Because the temperature range for processed steam is narrow — from 100 to 225 degrees Celsius (212 – 457 F) — as compared with temperatures needed to produce steel, for example, the partners saw an opportunity. Using electric heat pump technology, their company has developed a modular unit that will produce steam useful for multiple applications.

The first application, with a pilot unit to be built at the company’s new facility at the Forge Campus, will be used at New Belgium Brewing Co. Inc. The one-ton of steam per hour boiler at 165 degrees Celsius will accommodate about one-third of the need for steam at New Belgium, he said. The heated water will be used to boil grain and hops, for sterilization and other purposes at the brewery. Delivery of the unit is scheduled for 2026.

The one-ton boiler will have multiple applications because most — 65%, he said — of manufacturers have a small need.

Stark said that district steam — such as those used in downtown districts or on college campuses to heat buildings — are “a huge opportunity” but not in the company’s first rollout of boilers.

The pilot unit will fit on a 20-foot skid and will be larger than a traditional boiler but will likely be installed not in a boiler room but outside or on a rooftop.

Stark said that CSU has been essential to development of the technology. As an Iowa farm boy and a graduate of the Massachusetts Institute of Technology, he said CSU offered something that MIT did not: practical resources.

“People who build first, not theorists,” he said. People coming out of the oil and gas industry or from industrial backgrounds are readily available in Northern Colorado, he said.

Read related story.

AtmosZero Inc., is one of four winners of BizWest’s IQ (Innovation Quotient) Awards, which were unveiled in May 2024.