Product testing helps EMC Integrity make waves

LONGMONT — If you’re old enough to remember waves on the television screen when your mom was running the cake mixer, or even just had a cell phone call garbled in a high-density zone, you may appreciate the science behind one of Longmont’s most high-tech companies.

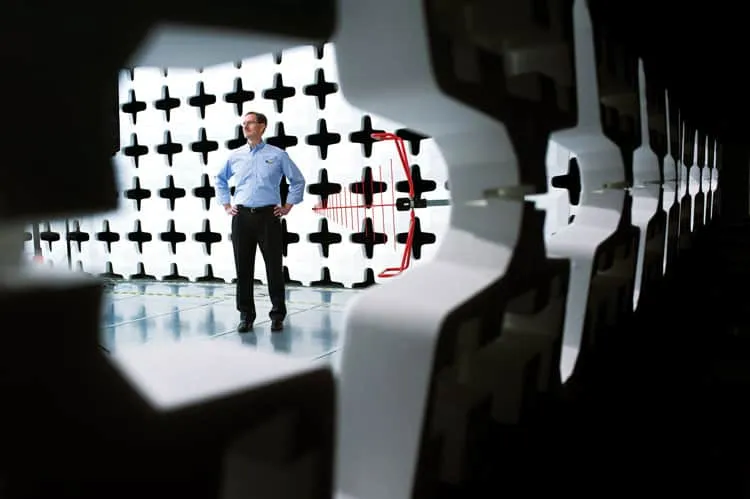

EMC Integrity Inc. is in the business of testing products for “electromagnetic compatibility,” or EMC, meaning the generation and reception of electromagnetic energy and its negative effects on manufactured products. Testing for EMC is required by a variety of national and international governing bodies such as the Federal Communications Commission, much in the same way…

THIS ARTICLE IS FOR SUBSCRIBERS ONLY

Continue reading for less than $3 per week!

Get a month of award-winning local business news, trends and insights

Access award-winning content today!